As part of the European Commission’s 1.4 billion pledge for the Coronavirus Global Response, CO-VERSATILE is one of the four projects funded under H2020 SC1-PHE-CORONAVIRUS-2020-2A initiative to repurpose manufacturing for vital medical supplies and equipment to support Europe in improving its response and preparedness to deal with pandemics.

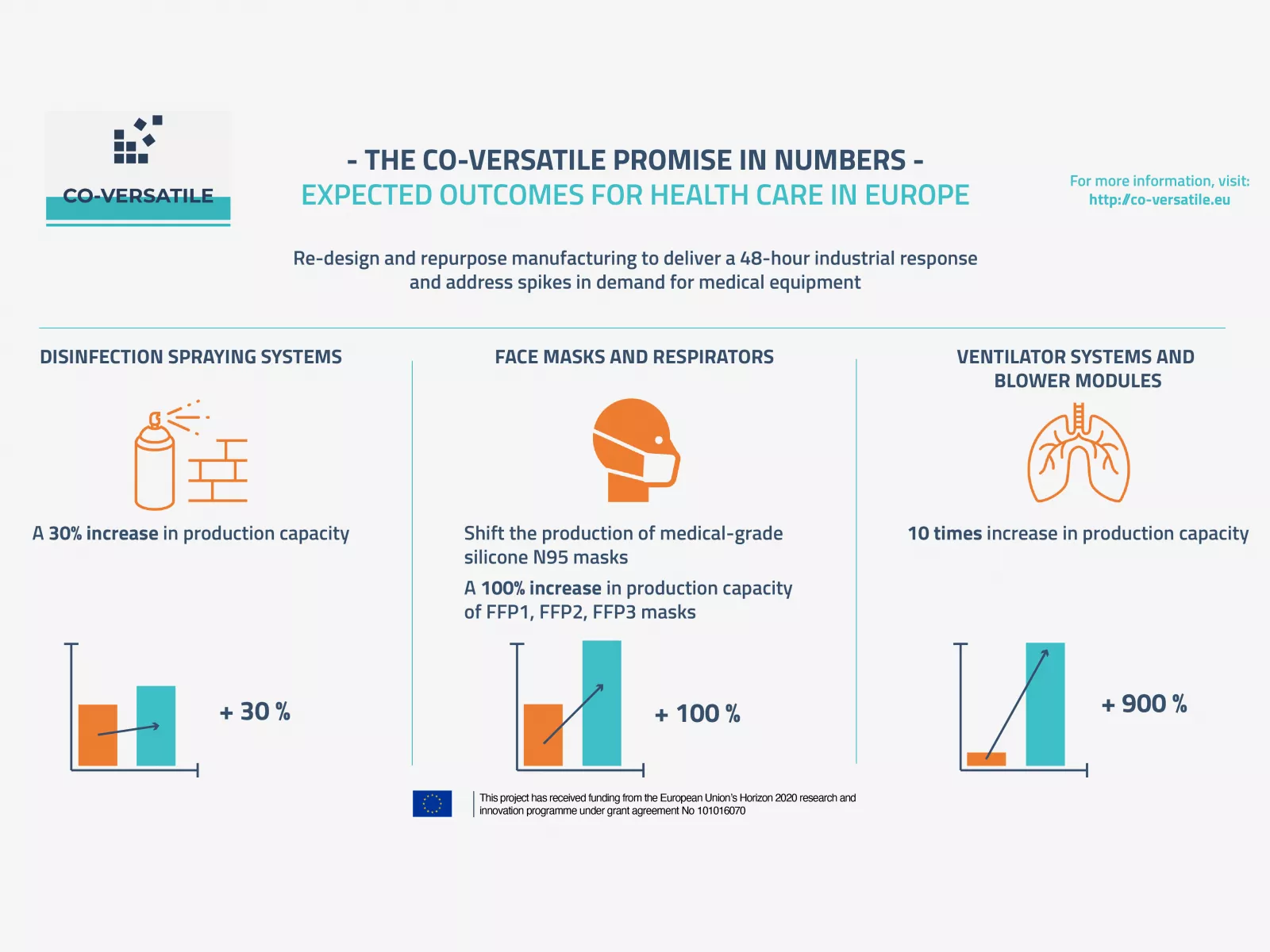

CO-VERSATILE builds upon current and past industry-driven research and innovation initiatives to deliver a flexible 48-hour industrial response and address sudden spikes in demand for strategic medical products. CO-VERSATILE expected outcomes for healthcare provisioning in Europe include a significant increase in production capacity of:

- disinfection spraying systems (by 30%),

- FFP1, FFP2, FFP3 face masks and respirators (by 100%),

- and ventilator systems (by 900%).

To deliver quick results to the European society, the CO-VERSATILE consortium of 21 partners innovate and deploy sustainable production methods and supply chain solutions to achieve large-scale utilisation and enable a wide range of institutions to battle pandemics, such as COVID-19. At the heart of the solution is a commercial marketplace - a democratic ‘Digital Technopole’ to quickly assist manufacturers with readily available solutions, including software and services tools.

CO-VERSATILE project represents a ‘model case’ for combining academia and industrial resources effectively. CO-VERSATILE leverages the Lean Start-up methodology, and the developments are broken down into iterative several Build-Measure-Learn three-month-long cycles.

During the first two months of the project the following progress has been achieved:

- For silicone masks, the requirements of the final product have been identified based on the analysis of the masks market and the drawbacks of the existing solutions. Solid silicone has been defined as the material to be used. A first prototype has been 3D printed and three possible textures have been identified for the finishing of the internal surface. The future work includes detailing the improvements to be done in the next iterations. The simulation of the manufacturing process has been done for the production of the machine manufacturing reconfigurable masks.

- For electrostatic disinfectant spray system, a sensorized testbench has been set up. In the first weeks of the project, the key parameters for testing have been identified, and a preliminary prototype was built. Additionally, the components for the next prototype of the spray system were selected, and the basic design criteria were identified, based on experimental data measures gathered.

- For ramping up production of respiratory devices, the main focus has been on the definition of the supply chain and its boundaries for the future improvement of production. In the next period, the supply chain will be modelled and simulated to better understand its optimisation path.

- For production automation of airflow generators for CPAP (Continuous Positive Airway Pressure) devices by a robotic cell, the progress so far has been based on the study of the manufacturing process for CPAP, the analysis of the SCALP (Small Component Assembly Loop) robotic cell, and the study of the middleware architecture for future integration with the CO-VERSATILE ‘Digital Technopole’. As a result, a set of operations that are worth carrying out automatically with the support of the SCALP robotic cell, were identified using 3D CAD modelling and drawing. Design of the middleware will start in the next few weeks.

The first Minimum Viable Products (MVP) for the above Manufacturing Settings have been defined based on the requirements of the CO-VERSATILE Manufacturing Settings owners, technology providers and competence centres. The action plans to guide their implementation in the first Build-Measure-Learn cycle are completed.

To offer manufacturing companies readily available solutions for repurposing and replication, CO-VERSATILE will also focus on developing content and adapt multimedia means for training employees on the new technologies and production protocols. To date, preliminary requirements have been collected. Additionally, activities related to the certification of materials, products and processes that are required to perform business repurposing, have been identified.

CO-VERSATILE is guided by IPR, GDPR and generic ethics standards and principles. To date, the project data management plan and its code of conduct have been completed. Future work will focus on the supervision of the code of conduct and the monitoring of gender issues, encouraging partners to implement long-term institutional changes by adopting measures outlined in GEAR (Gender Equality in Academics and Research) as well as the UN Sustainability Development Goal #5 - Gender Equality.

FFP1 - Face mask that filters at least 80% of airborne particles

FFP2 - Face mask that filters at least 94% of airborne particles

FFP3 - Face mask that filters at least 99% of airborne particles

Elena Leinemann, CO-VERSATILE Communication manager

Email: elena.leinemann (at) eitmanufacturing.eu

Phone: +49 6151 38441 46